BUSINESS

CX Solution predicts breakdowns in power facilities and conducts preventive diagnosis to prevent them.

Gridsol AMS

LS ELECTRIC's GridSol AMS provides total care services throughout the life cycle of power equipment.

Gridsol AMS helps in establishing management, maintenance plans and investment plans through 24-hour monitoring and asset management through constant monitoring of each asset.

Download CatalogDownload Catalog

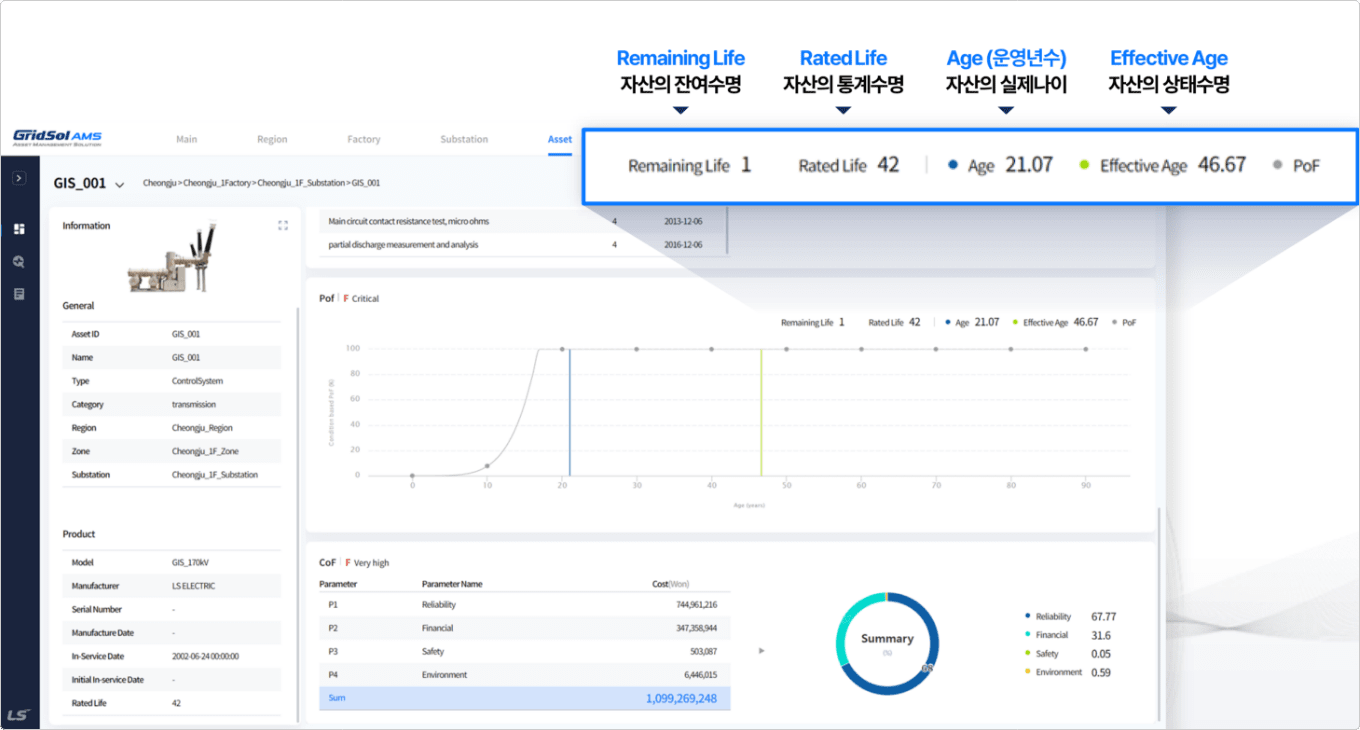

We provide customers with investment priorities and optimal maintenance plans based on physical performance evaluations such as failure rates, remaining lifespans, and replacement cycles of power facilities, and economic evaluations such as maintenance, breakdowns, and social costs.

-

Quantified power facility life evaluation

Providing age information through status and history analysis for each facility

Asset status and performance analysis by asset class type or tier

-

Failure Probability and Risk Management

Review the probability of future failure for each facility and the impact of failure in the event of a failure

Calculate risks for each facility and establish an optimized maintenance strategy

Contributes to life extension and reduces maintenance costs

-

Maintenance strategy can be established

Prioritize maintenance across your entire asset

Improving and Repairing(Overhaul, Renewal) and Suggest costs associated with replacement

-

Present objective basis when deciding on replacement of old equipment

Determination of optimal replacement time based on risk for each facility

Reduce investment costs for old replacement and improve investment effectiveness

Reduce the work time required to select equipment for old replacement

GridSol AMS Performance

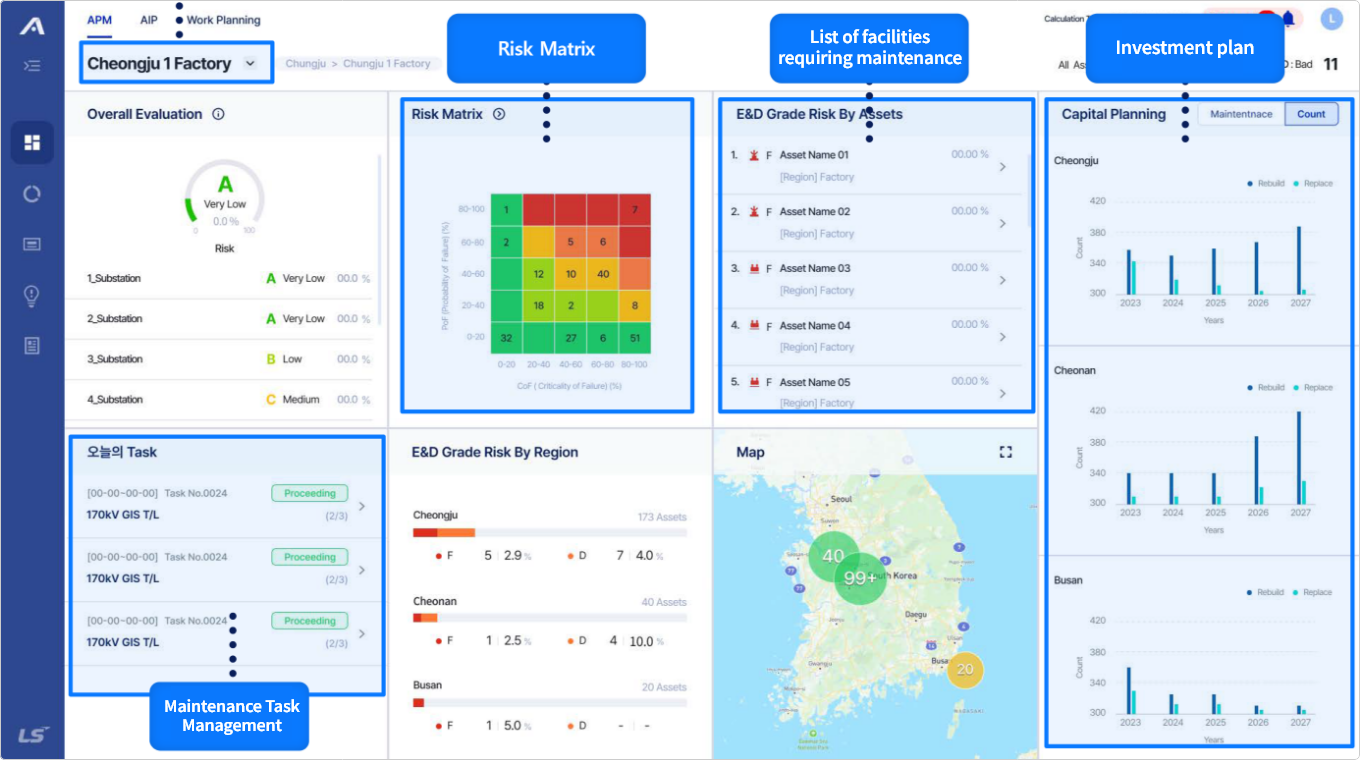

GridSol AMS can manage customer assets distributed at domestic and overseas business sites by region, business site, and substation asset.

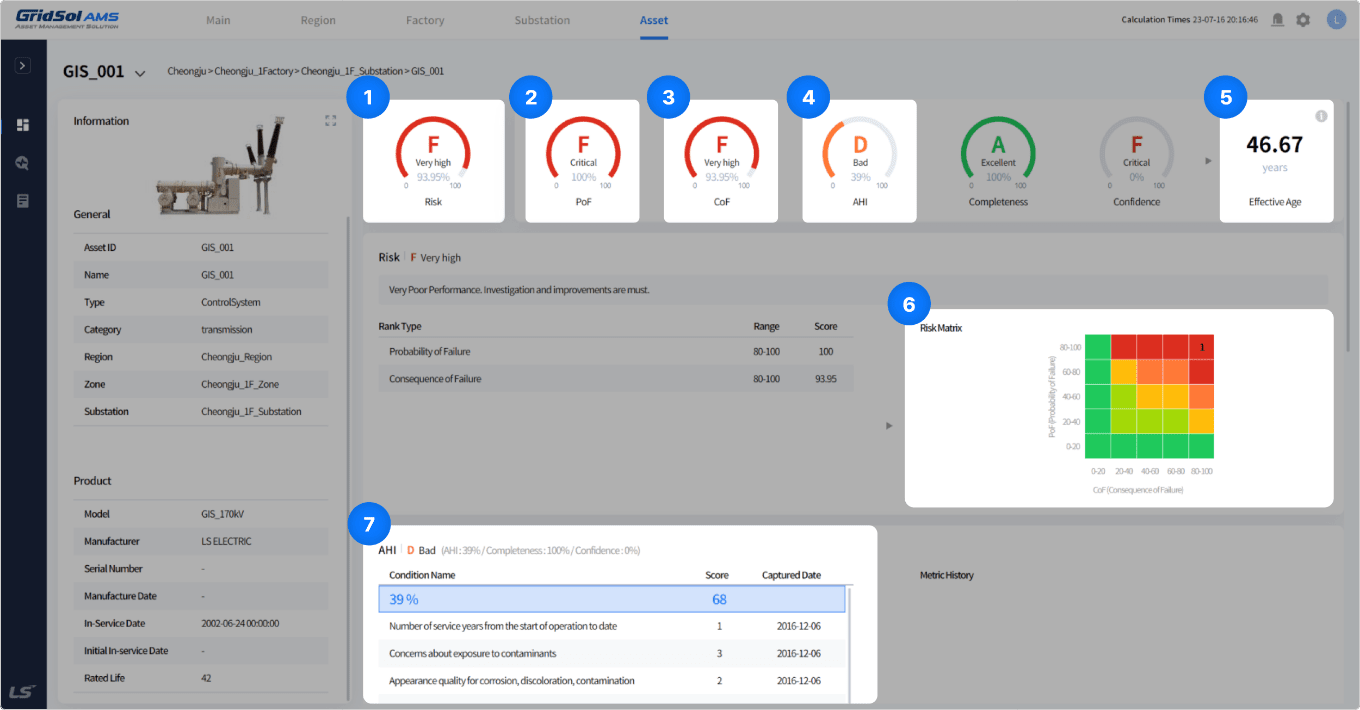

GridSol AMS evaluates the probability of failure (PoF) and impact of failure (CoF) of assets and analyzes the risks of each facility using the Risk Matrix technique to objectively provide priorities for maintenance and investment.

- 1 Risk Grade Asset Risk Analysis

- 2 Probability of Failure Asset Failure Probability

- 3 Consequence of Failure: Asset Failure Impact Assessment

- 4 Asset Health Index Asset Soundness Index

- 5 Effective Age Asset Risk Analysis

- 6 Risk Matrix Analysis

- 7 Health Index Detailed Item

Power Equipment Diagnosis & Preventive System

The recent changing technology trend is the intelligence and digitalization of power systems through rapid convergence and integration between power facilities and IT technologies. The LS Power Facility Prevention Diagnostic System is an optimized solution for substation power facility management that can predict failures by acquiring/analyzing data through real-time status monitoring to prevent sudden power outages and respond quickly to failures. LS will show differentiated services for stable power facility operation based on the nation's best heavy electric machine manufacturing/production technology and core Algorithm technology through continuous technology development.

Download CatalogPSmart and Wide Area Diagnosis System

LS's Compact Smart Diagnostics System is the best solution to improve system reliability by proactively monitoring/diagnosing major component defects/systematic environmental or natural degradation of distribution boards. The uninterruptible maintenance following the installation of no holes enables real-time facility monitoring of aging distribution-grade power facilities in operation, enabling stable facility operation and productivity expansion 24 hours a day and 365 days a year. The establishment of a web-based wide-area monitoring system enables integrated monitoring of domestic/foreign workplaces to quickly identify whether there is a facility abnormality anytime, anywhere to support stable facility operation.

Download CatalogSmart & Wide Area Combined Diagnosis System

LS ELECTRIC's integrated transmission/distribution wide area monitoring diagnostic system is the best solution to ensure system reliability and stability in facility operations by proactively monitoring/diagnosing major component defects/systematic environmental or natural degradation. The establishment of a web-based wide area monitoring system enables integrated monitoring of domestic/foreign workplaces and supports stable facility operation by quickly identifying whether or not there is an abnormality in the facility anytime, anywhere.

Download Catalog